Accelerating Sustainable Infrastructure With Ductal Ultra-High-Performance Concrete

The pressing goal today is to make cities more sustainable while simultaneously improving the quality of life for residents. A key element in achieving this is the transition to net-zero emissions, which requires significant innovation across various infrastructure sectors, particularly for roads and bridges. Major initiatives, such as the CAD 3.9 billion Alto high-speed rail project connecting Toronto and Quebec and the twinning of the Garden City Skyway bridge, highlight the growing demand for innovative high-performance materials that align with sustainability goals. Innovation is a catalyst for meeting sustainability targets and addressing the growing infrastructure needs while aiming to improve efficiency and safety.

As a leader in sustainable and innovative solutions, Lafarge Canada is committed to enhancing the life span of current and future infrastructure projects, while reducing their environmental impact. A key advancement in this mission is the evolution of Ductal, Lafarge Canada’s Ultra-High Performance Concrete (UHPC). Extensive research and development at our Innovation and Training Centre (ITC) has led to a significant breakthrough, transitioning Ductal UHPC to a more sustainable, cost-effective mix using locally sourced Canadian materials.

A More Sustainable and Cost-Effective UHPC

By shifting to a Canadian-sourced, Lafarge has succeeded in reducing the Global Warming Potential (GWP) of the Ductal UHPC mix by 35%, a significant step in lowering the carbon footprint of infrastructure materials.

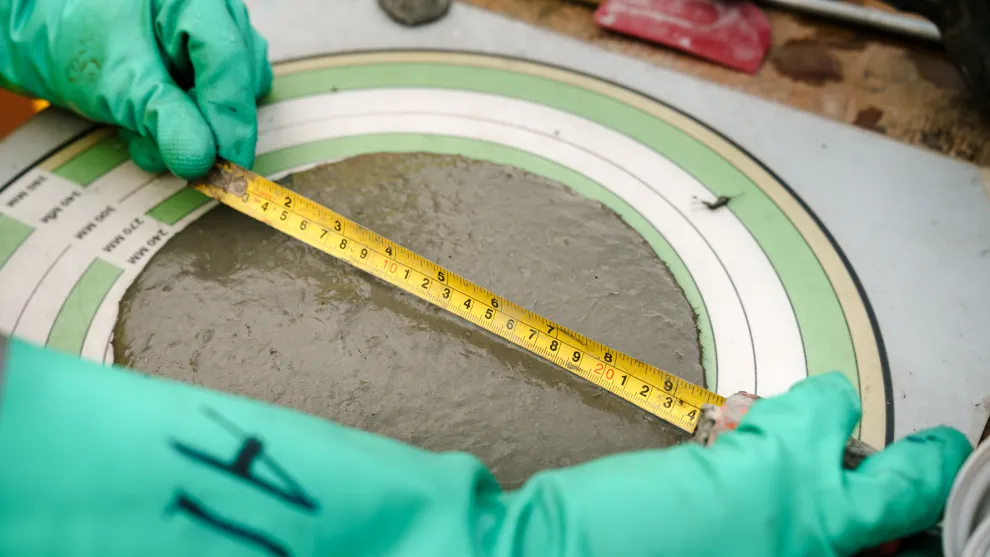

This achievement is a result of rigorous research by the Lafarge Innovation and Development team, with over 20 different material sources evaluated to develop the optimal mix. Extensive testing ensured that the new sustainable formulation maintains the strength, durability and resilience required for critical infrastructure applications.

Key performance highlights of the sustainable Ductal UHPC mix include:

- Compressive strength exceeding 130 MPa

- Flexural strength of 17 MPa, meeting industry requirements

- Exceptional durability, with RCPT below 50 MPa and minimal shrinkage

- 100% resistance to freezing and thawing cycles

- Abrasion resistance below 0.5 kg/m².

This transition to the advanced formulation ensures that the Ductal mix meets the CSA/MTO and MTQ requirements for UHPC, which is an important step toward widespread adoption in infrastructure projects across Canada.

Real-World Applications: The PIAT Project

Lafarge is set to deploy its sustainable Ductal UHPC mix in large-scale infrastructure projects, starting with the PIAT project in the Greater Montreal Area (GMA). This three-year initiative, scheduled to begin in mid-2025, focuses on joint-fill repair for a critical bridge between Montreal Island and Vaudreuil-Dorion. The project will serve as a real-world testing ground for the sustainable mix, providing valuable insights into its performance in high-stress environments.

Through innovation in materials and supply chain transformation, Lafarge Canada is not only addressing the environmental impact of construction but also ensuring the resilience and efficiency of infrastructure for years to come. The sustainable Ductal UHPC mix marks a major step forward in advancing net-zero infrastructure solutions while maintaining the highest performance standards. As cities continue to evolve, these innovations will play a crucial role in shaping the next generation of sustainable infrastructure across Canada.