Lafarge Canada Advances Sustainable Construction with ECOPact MAX

ECOPact MAX with 99.2% Clinker-Free Cement achieves 97 kg CO2eq per meter compared to an industry average of 379 kg CO2eq.

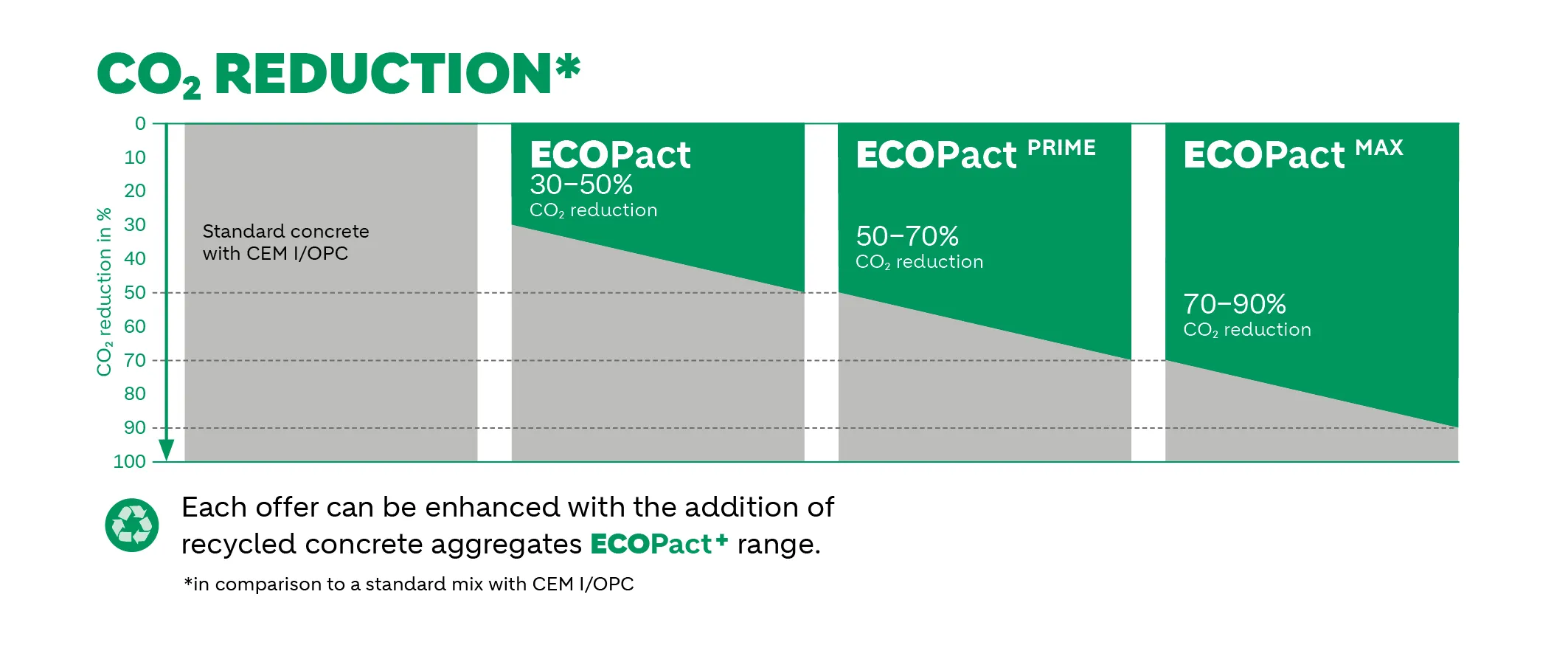

Lafarge Canada’s ECOPact concrete range, launched in 2021, includes ECOPact, ECOPact Prime, and ECOPact MAX—each designed to progressively reduce concrete’s carbon footprint. This structured approach was built to compare concrete from a carbon perspective from two opposite vantage points: today's industry average within Canada or a region and the ultimate goal of zero-carbon concrete (ECOPact Zero). ECOPact MAX, in particular, delivers a 61% reduction in embodied carbon compared to Lafarge standard designs at 247 kgCO2eq and 74% lower than the published industry benchmark of 379 CO2eq through CRMCA.

Recently, Lafarge’s Vancouver Fraser Valley operations team conducted a flatwork trial in Abbotsford, British Columbia, using 28 cubic meters of ECOPact MAX with 99.2 percent clinker-free cement solution. Working together with Caliber Concrete and Alpha Concrete Pumping, the trial tested placement and pumpability, achieving results that opened the door for more extensive testing in upcoming projects.

“We aim to deliver a low-carbon concrete that meets the everyday needs of our direct customers who build. Our low-carbon concrete with this cement material is designed to meet both sustainability goals and the practical needs of everyday construction.”

This 99.2 percent clinker-free cement solution, developed by Lafarge Western Canada’s Innovation Hub in Edmonton and Cement Technical Centre in Seattle, represents a significant step forward for Lafarge’s sustainability ambitions.

“While these materials have advanced over the years, it has not traditionally been used in larger, ready-mix applications such as buildings. As the industry shifts toward lowering embodied carbon in construction, we are finding that this material represents a promising pathway forward.”

To achieve ECOPact’s full potential, Lafarge’s technical team recognizes the importance of working with the design community to interpret CSA and ASTM with specifiers and owners regarding concrete with no Portland cement content. Alternative Supplementary Cementitious Materials (ASCM)—constituents that exhibit pozzolanic or hydraulic properties—can meet the intent of CSA A3004-E1 and ASTM 1157. Additionally, this material qualifies as a standard ground granulated blast furnace slag under CSA standards. Owners will play a key role in creating opportunities for 99.2% clinker-free cement within the ECOPact product family.

“As we continue our journey toward ultra-low carbon materials, ECOPact concrete with 99.2% clinker-free cement represents a significant advancement in our efforts to decarbonize building, moving beyond conventional technology. This material aligns with our larger sustainability goals, and we are excited to be able to work closely with our innovation teams to explore its full potential.”

Future projects will focus on concrete designed for conventional walls and footings. The concept targets applications that will consume large amounts of concrete within a given project, positively impacting a carbon budget. Following these trials, the team will work to develop an Environmental Product Declaration (EPD) to represent the product’s environmental impact.